Plastic knowledge

8 most common plastic additives

Plastic is a versatile material used in a variety of products, from packaging to construction materials. However, in order for plastic products to achieve special functions or unique characteristics, they must rely on additives. There are many types of additives used in the plastic industry. In this article, let’s learn about the 8 most common plastic additives.

I. What are plastic additives?

Plastic additives are substances added to plastic materials to enhance or change their properties during processing. These additives can be classified into many types, including stabilizers, plasticizers, flame retardants, etc. In general, plastic additives help manufacturers produce plastic products with many diverse properties and applications.

II. Common types of plastic additives

1. UV Stabilizers

Anti-UV additives, also known as ultraviolet stabilizers, are additives used in plastic materials to protect plastic products from the harmful effects of ultraviolet (UV) radiation. Ultraviolet radiation from the sun can cause plastics to degrade, leading to discoloration, brittleness and loss of mechanical properties. This is a major concern for outdoor applications such as automotive, construction, and agriculture.

There are two main types of UV stabilizers used in plastics: UV absorbers and hindered amine light stabilizers (HALS). UV absorbers work by absorbing UV radiation and converting it into harmless heat, while HALS works by eliminating free radicals formed during UV breakdown.

2. Antistatic additives

Antistatic additives for plastics are chemical compounds added to plastic materials to reduce or eliminate the buildup of static electricity. Static electricity can cause a number of problems in plastic products, including the ability to attract dust and dirt, difficulty handling and hindering the manufacturing process, as well as potential hazards in explosive environments.

Antistatic additives work by increasing the electrical conductivity of the plastic, allowing any electrostatic charge to dissipate more easily. These additives are commonly used in various plastic applications, including packaging, electronics, and automotive components.

Overall, antistatic additives play an important role in improving the performance and safety of plastic products in various industries.

3. Desiccant

Moisture is a common problem in plastic manufacturing, as it can lead to defects and damage to the final product. To solve this problem, moisture-proof additives, also known as desiccant additives, are often added to plastic materials during the production process. These additives help prevent moisture from affecting the quality of the plastic, ensuring the final product meets required standards.

4. Antiblock additive

Anti-block additives, are commonly used in the plastics industry to prevent adhesion of plastic films or sheets. These additives are often made from inorganic materials such as silica, talcum powder or diatomaceous earth. They are added to plastics during the manufacturing process to create microscopic roughness on the surface of the film or sheet, which reduces the coefficient of friction and prevents clogging. This allows for easier handling and processing of plastic materials.

Anti-blocking additives are widely used in the production of various plastic products such as food packaging, agricultural films and industrial films. They play an important role in improving the performance and quality of plastic materials.

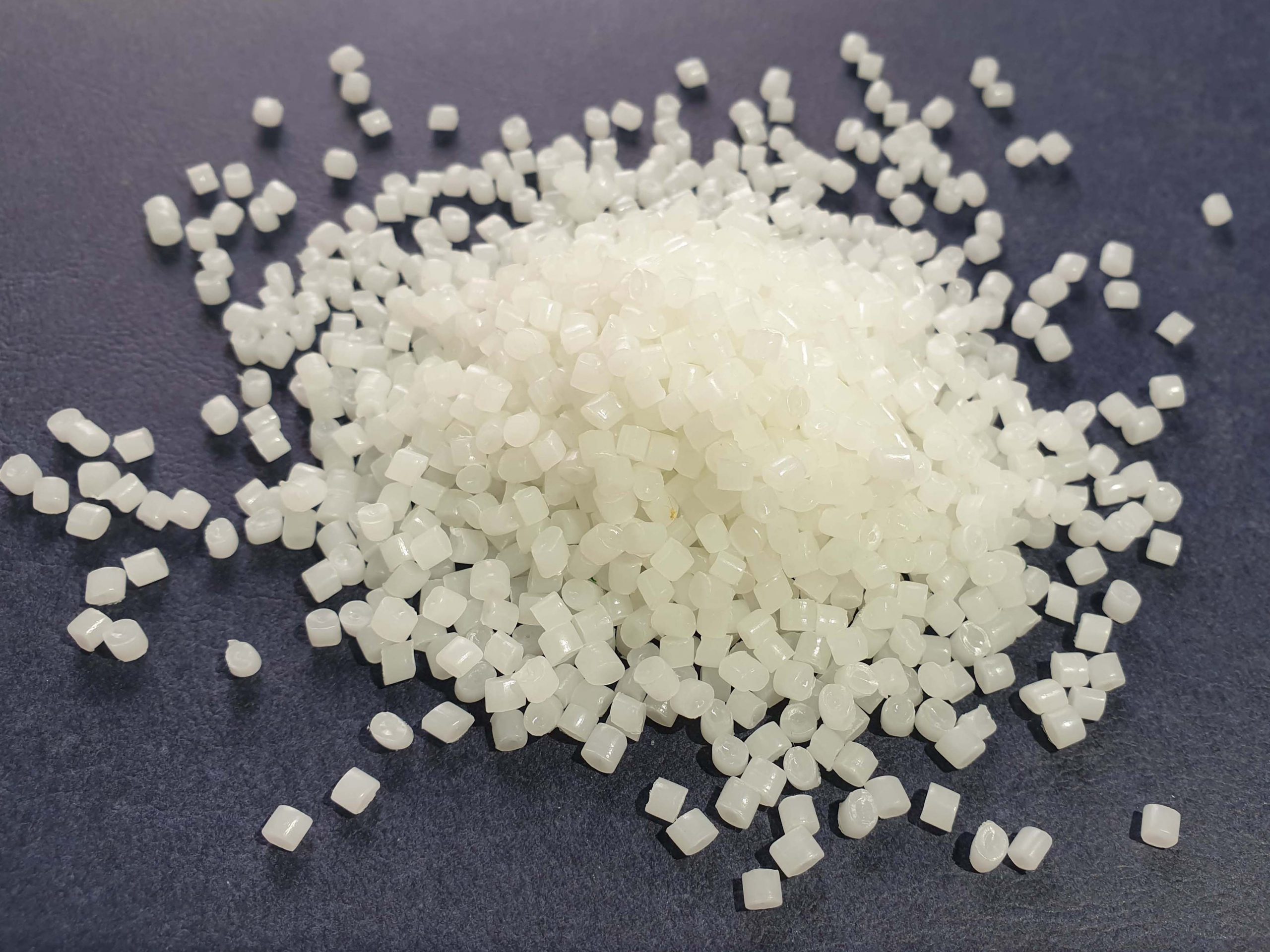

5. Processing aids additive

Processing aids additive (PPA) are a type of additive used in the plastics industry to improve the processing and performance of plastic materials. PPA additives are commonly used to enhance flow characteristics, reduce melt viscosity, and improve dispersion of fillers and colorants in plastic compounds. These additives can also help improve the thermal stability and mechanical properties of plastic materials.

PPA additive is widely used in various plastic processing methods such as injection molding, extrusion and blow molding. They are available in different forms such as tablets, powders and liquids and can be easily incorporated into resin formulations to achieve desired properties.

6. Flame retardant additives

Flame retardant additives for plastics are chemical compounds added to plastic materials to reduce flammability and slow the spread of fire. These additives work by creating a physical barrier that prevents the plastic from igniting or by releasing inert gases or water when burned.

These additives are widely used in various industries, including construction, automotive and electronics, to improve the fire safety of plastic products.

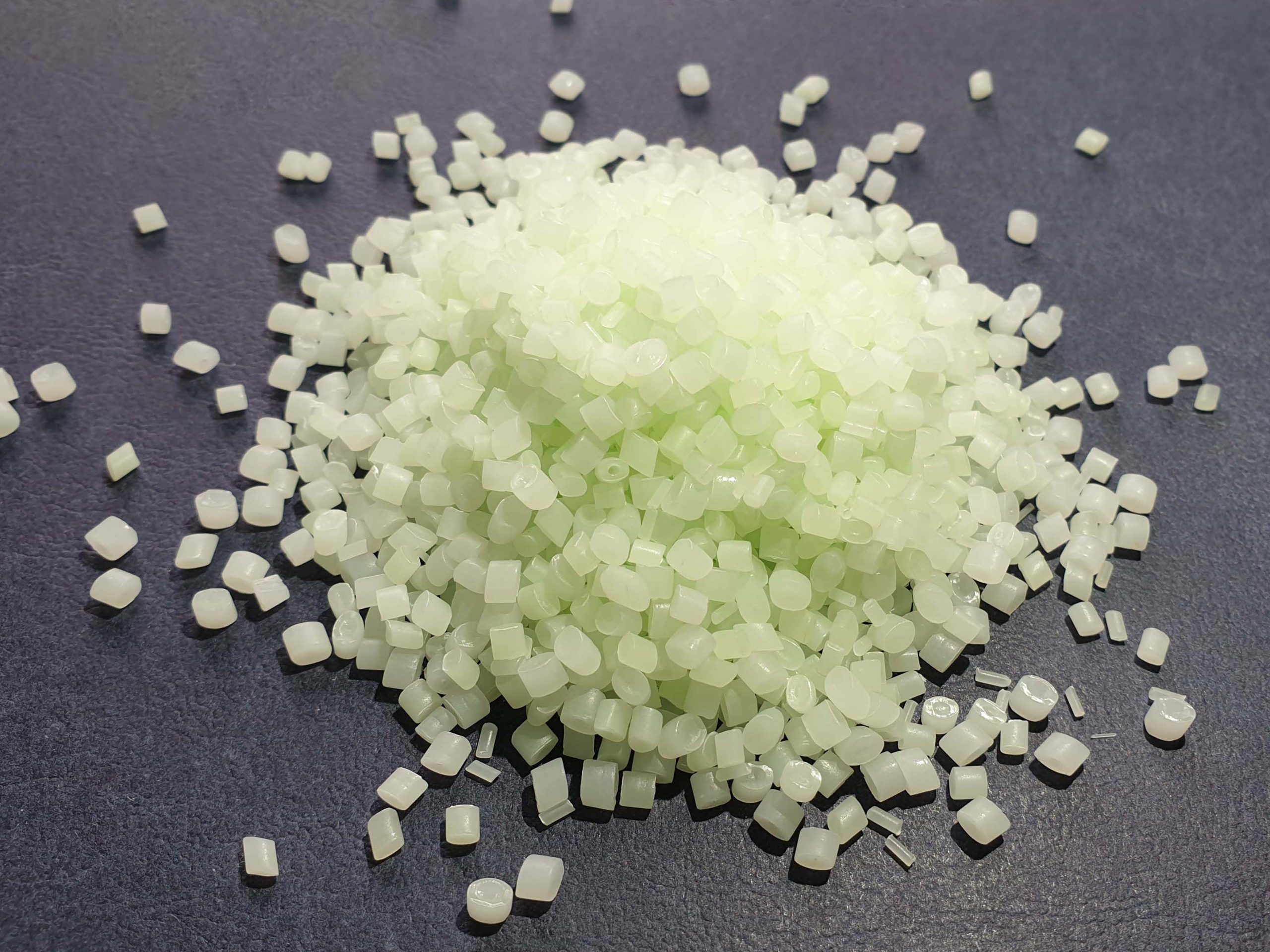

7. Whitening additive

Plastic whitening additives are chemicals added to plastic materials to enhance their whiteness and brightness. These additives work by absorbing ultraviolet rays and emitting blue light. The blue light reflected from the product to the human eye covers the orange-red light area, giving the plastic a brighter and more attractive appearance.

Whitening additives are commonly used in the production of various plastic products, such as containers, packaging materials, and consumer goods. They are also used in the production of plastic films and sheets for printing and packaging applications. The use of whitening additives is an effective method to improve the aesthetics of plastic products, making them more attractive to consumers.

8. Blowing agent

Blowing agent for plastic, also known as foaming agent, is an important ingredient in the production of foam products. This specialized powder is added to plastic during the manufacturing process to create a cellular structure within the material, creating a lighter and more insulating final product. The expansion process allows for reduced material usage while maintaining the overall strength and integrity of the plastic.

Expanded plastic powder is commonly used in the production of packaging materials, insulation materials and various consumer goods. This is a flexible and cost-effective solution for creating lightweight and durable plastic products.

CPI Plastics Vietnam is the largest direct manufacturer of Masterbatch plastic additive products in Vietnam. Therefore, CPI Plastic is the top choice for factories that need stability in output and quality, to meet the production and export needs of customers.

(Customers can find out products here: Additives for the plastic industry)