Plastic knowledge

Antistatic additives – Solutions to minimize the effects of static electricity for plastics

To minimize the impact of static electricity on plastic products, the most commonly used method is to use antistatic additives for plastics.

Static electricity is a phenomenon that often occurs when certain materials rub against each other, causing electron transfer. This displacement creates a buildup of charge on the surface of the material, which can lead to attraction or repulsion of other objects. Static electricity in plastics can be a nuisance in industrial processes because it can cause dust and debris to adhere to surfaces, leading to production problems. It can also pose a safety hazard in certain environments because it can create sparks that can ignite flammable materials.

I. What are antistatic additives?

Antistatic additives are a type of chemical compound used to reduce or eliminate static electricity in materials. This additive is commonly used in plastics, textiles, and other materials that easily accumulate electrical charge. Antistatic additives work by increasing the electrical conductivity of the material, allowing any electrostatic charge to dissipate more easily. This helps prevent problems such as dust build-up, handling difficulties, and potential damage to electronic components.

II. Classification of antistatic additives for plastics

1. Internal antistatic agent

Internal antistatic agents are additives that are incorporated directly into the plastic during the manufacturing process. They work by migrating to the surface of the plastic, where they form a conductive layer that helps dissipate any static charge that may have built up. internal antistatic agents are effective against many types of plastics and are often used in applications requiring long-lasting antistatic properties.

2. External antistatic agent

External antistatic agents are additives that are applied to the surface of plastic after it is manufactured. They work by forming a thin conductive layer on the surface of the plastic, helping to dissipate any static charge that may build up. External antistatic agents are commonly used in applications where a temporary antistatic effect is required, such as in packaging materials.

III. Benefits of using antistatic additives in plastic production

1. Improve safety

One of the main benefits of using antistatic additives in plastic products is improved safety. Static electricity can pose a serious risk in certain environments, such as in explosive or flammable environments. By reducing or eliminating static electricity, antistatic additives can help prevent accidents and protect workers from harm.

2. Enhances durability and appearance

Another important benefit of antistatic additives is improved durability. Static electricity can damage plastic materials over time, leading to cracks, breaks, and other forms of wear and tear. By reducing the build-up of static electricity, antistatic additives can help extend the life of plastic products, making them more cost-effective in the long run.

Static electricity can also cause dust and other particles to adhere to plastic surfaces, resulting in a dull or dirty appearance. Antistatic additives can help reduce the build-up of static electricity, keeping plastic products looking clean and shiny. This can be especially important for products used in consumer-facing environments, such as display goods or retail packaging.

3. Easy processing

Static electricity can also make plastic products more difficult to handle, especially in industrial or manufacturing environments. Antistatic additives can help reduce static charges on plastic materials, making them easier to handle and transport. This can improve productivity and reduce the risk of product damage during processing.

IV. Application of antistatic additives for plastics in industries

1. Electronics

Electronic components are often made of plastic, and static electricity can damage these sensitive parts. By incorporating anti-static additives into plastics, manufacturers can ensure that their electronic products are protected from static build-up, improving overall performance and longevity.

2. Packaging

Plastic packaging materials, such as bags, films, and containers, can create static electricity, leading to problems such as dust collection, product sticking, and even fire hazards in certain environments. By adding antistatic additives to plastic packaging materials, manufacturers can prevent these problems and ensure that their products remain safe and functional.

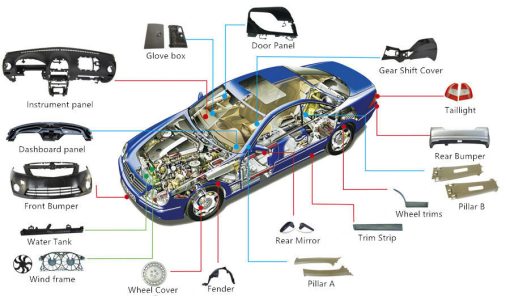

3. Automobile industry

Many car parts such as the dashboard, seats and interior trim details are made of plastic. Static electricity in these parts can cause passenger discomfort as well as potential safety hazards. By incorporating antistatic additives, manufacturers can create a more comfortable and safer driving experience for consumers.

4. Other industries

Other industries that benefit from the use of antistatic additives in plastics include the medical and healthcare industry, where static electricity can interfere with sensitive medical devices, and the manufacturing industry , where static electricity build-up can cause manufacturing delays and defects in plastic parts.

CPI Plastic Vietnam is the largest direct manufacturer of Masterbatch plastic additive products in Vietnam. Therefore, CPI Plastic is the top choice for factories that need stability in output and quality, to meet the production and export needs of customers.

(Refer to the product here: Antistatic Masterbatch)