Plastic knowledge

Blowing agent – Indispensable additive for plastic foam production

Blowing agent is an indispensable additive in the production of plastic foam. Let’s learn how to operate of baking powder and the functions of this additive in the article below.

I. How blowing agent for plastic work

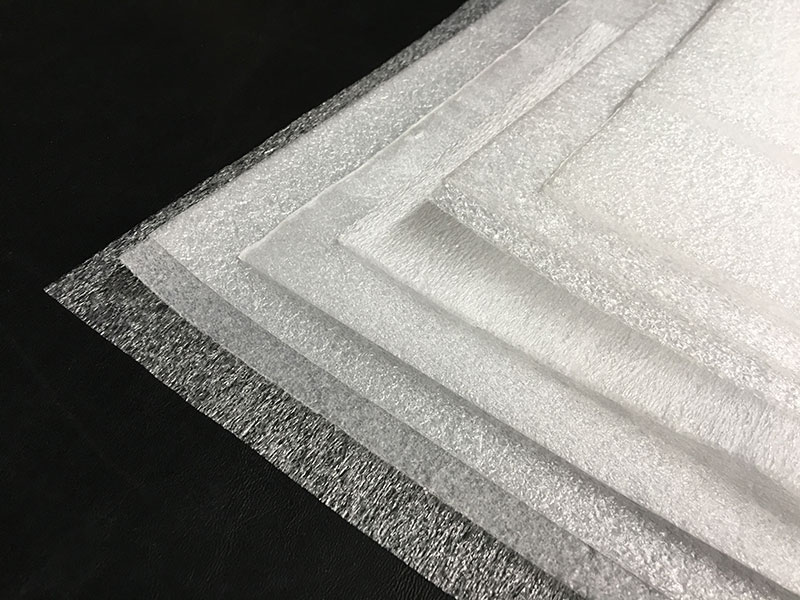

The porous or blowing agent is added to the plastic material to create the cell structure inside the material. When the plastic is heated, the baking powder will release the gas, forming a bubble inside the plastic. These bubbles help reduce the density of the material, forming a porous structure.

II. The popular blowing agent for plastic

A. Chemical blowing agent

Chemical blowing agents are the most commonly used porous substances in plastic production, often in the form of powder. They are usually added to the plastic in the mixing stage or extruding and they decompose when exposed to heat, releasing gas into the plastic. The gas then expands and produces airbags in plastic, forming a porous product. Some of the commonly used chemical foam agents include azodicarbonamide (AC), sodium bicarbonate (NC) and Xitric Acid.

B. Physical blowing agent

Physical porous agents are substances that are added to liquid plastic and they evaporate when exposed to heat. The evaporation of liquid creates air bubbles in plastic, forming a porous product. Physical foam substances are often used to produce high density foam and they include substances such as hydrocarbon, fluorocarbon and hydrofluorocarbon.

C. Water blowing agent

Water porous agents are substances added to the plastic in the form of solution, they decompose when exposed to heat, releasing steam into plastic. Steam then expands and creates airbags in plastic, forming porous products. Water porous agents are often used in low -density foam production and they include substances such as sodium bicarbonate and cubic acid.

III. Other effects of blowing agent for plastic

A. Reduce the weight of the product

The porous agent helps reduce the density of the plastic, making it lighter and more cost -effective when producing. This is especially important in industries such as cars and aerospace, where light materials are very important for performance and efficiency of fuel use.

B. Improving insulation, soundproofing

The porous substance also improves the thermal and soundproofing properties of the plastic, making it an ideal material for applications such as insulation and sound insulation in the house. In addition, the cell structure is produced by blowing substances that can enhance the mechanical properties of the plastic, making it more durable and impact resistant.

C. Improve aesthetics

Moreover, foaming agents can also improve the aesthetics of plastic in some special applications, such as decorations, interior.

CPI Plastic Vietnam is the largest manufacturer of Masterbatch plastic additives in Vietnam. Therefore, CPI plastic is the first choice for factories that need stability in production and quality, in order to meet the production and export needs of customers.

(Refer to the product here: Blowing agent)