Plastic knowledge

LDPE Plastic: What You Need to Know

LDPE plastic is a plastic material widely used in many areas of life, especially in the field of packaging and daily utensils. Therefore, there are many concerns such as what LDPE plastic is and whether LDPE plastic is safe. This article will give you the answers as well as provide the necessary information about LDPE plastic.

I. What is LDPE plastic?

LDPE stand for Low-density polyethylene, it’s a thermoplastic produced from monone ethylene; Made of PE plastic with low density. This was the first type of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high-pressure process through free radical polymerization.

Although there are many new types of plastics being created today, LDPE is still an important plastic in life and production.

II. Characteristics of LDPE plastic

Lower density than other types of PE – LDPE is defined by a density range of 917–930 kg/m3, lower than HDPE (930 ~ 970 kg/m3). LDPE is more branched, resulting in weaker intermolecular forces and less crystalline molecules.

(LDPE Structure)

Tough and flexible – Due to weaker molecular binding forces than other types of PE, it has lower tensile strength and higher recovery ability. Its flexibility allows it to be molded into a variety of shapes, making it ideal for manufacturing products such as plastic bags, films and containers.

Moisture and chemical resistance – LDPE is highly resistant to moisture and chemicals. This property makes it an excellent choice for packaging material as it can protect the contents from damage caused by moisture and chemical exposure. Additionally, LDPE is often used to line containers containing corrosive substances because it provides a reliable barrier against chemical reactions.

Recyclable – LDPE can be easily recycled and used to create new products, reducing waste and promoting sustainability. Recycling LDPE helps conserve resources and reduce the environmental impact of plastic waste.

III. Advantages and disadvantages of using LDPE plastic

A. Advantages

- Light weight, good impact resistance.

- Flexible, easy to stretch.

- Resistant to strong acids, alcohols, bases and esters.

- Good moisture resistance.

- Can be used to preserve food at low temperatures.

B. Disadvantages

- Flammable.

- Emits two greenhouse gases (methane and ethylene) when continuously exposed to sunlight.

- Low durability.

- Low heat resistance, high thermal expansion.

IV. Application of LDPE plastic

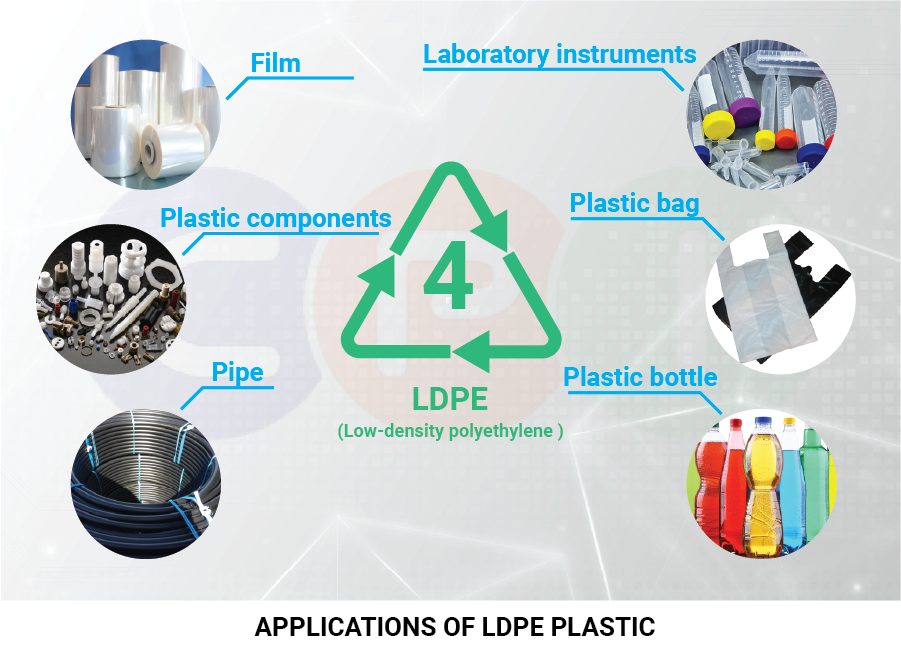

LDPE plastic is most widely used in the packaging industry, such as plastic bags and films, due to its flexible and lightweight nature. LDPE is also used in the manufacture of various household items, including squeeze bottles, toys, and disposable gloves; Used to produce medical equipment thanks to its excellent chemical resistance.

LDPE has a low melting point, making it a suitable material for injection molding and extrusion processes. In addition, it is also widely used in the construction industry for insulation purposes. Its moisture resistance makes it ideal for lining ponds, reservoirs and landfills.

Overall, LDPE’s durability and affordability make it a popular choice across a variety of industries. Other products made from LDPE include:

- Trays and containers.

- Anti-corrosion work surface.

- Parts need to be welded and machined.

- Parts require flexibility.

- Very soft and pliable parts like lids.

- Packaging for computer hardware, such as hard drives, video cards, and optical drives.

- Plastic bag.

- Plastic container.

- LDPE pipe.

- Houseware.

- Battery case.

- Automotive Parts.

- Electronic components.

V. Safety of LDPE plastic

LDPE plastic is often used in many everyday products, especially for food storage. Therefore, there are many concerns about the safety of LDPE plastic as well as its potential impact on human health.

LDPE is considered relatively safe for use in food packaging and other consumer products. It is approved by regulatory agencies, such as the Food and Drug Administration (FDA), for contact with food and beverages. LDPE is also widely used in medical devices, such as syringes, due to its inert and non-reactive nature.

One of the main reasons LDPE is considered safe is because it does not contain toxic chemicals such as phthalates or bisphenol A (BPA), commonly found in other plastics. These chemicals have been linked to a variety of health problems, including hormone disruption and reproductive problems.

However, it should be noted that when burned or exposed to high temperatures, LDPE can release toxic chemicals into the environment or seep into food. To prevent health risks associated with LDPE, use of LDPE containers for hot or acidic foods and beverages should be avoided.

VI. Impact of LDPE plastic on the environment

A. Non-biodegradable

Similar to other common plastics, LDPE does not naturally decompose over time. Instead, it persists in the environment for hundreds of years, contributing to pollution and litter. This is especially problematic because LDPE plastic is often used in single-use products, such as grocery bags, and is discarded after just one use. The accumulation of LDPE plastic waste in landfills and oceans poses a significant threat to ecosystems and wildlife.

B. Recycle LDPE plastic

Recycling LDPE plastic can help reduce its impact on the environment. LDPE plastic recycling involves collecting used plastic products, processing them, and converting them into new materials. This not only reduces the amount of plastic waste ending up in landfills and oceans, but also conserves resources and reduces energy consumption.

Recycling LDPE plastic offers several benefits. First, it helps conserve natural resources, such as oil, the main raw material used in plastic production. By recycling LDPE plastic, we can reduce the need to extract and refine more oil, thereby minimizing our environmental impact. Additionally, recycling LDPE plastic helps reduce the energy consumption and greenhouse gas emissions associated with the production of new plastic.

Furthermore, recycling LDPE plastic can contribute to the circular economy. By giving new life to used LDPE plastic, creating a closed-loop system in which the material is continuously reused and recycled, reducing the need for virgin materials and minimizing waste generation waste.

VII. summary

To summarize, LDPE plastic is a thermoplastic with low density, high flexibility and excellent chemical resistance. It is most commonly used to produce packaging products such as bags, films and containers. Overall, LDPE’s properties make it a versatile and cost-effective material for many applications.

LDPE plastic is also a safe plastic for health and is widely used in medical devices. It does not contain harmful chemicals and has a low environmental impact when used and managed properly.

Through the article, we hope you can better understand LDPE plastic, its properties and applications in life. Thereby, you can be more proactive in choosing consumer products as well as choosing suitable materials for production.