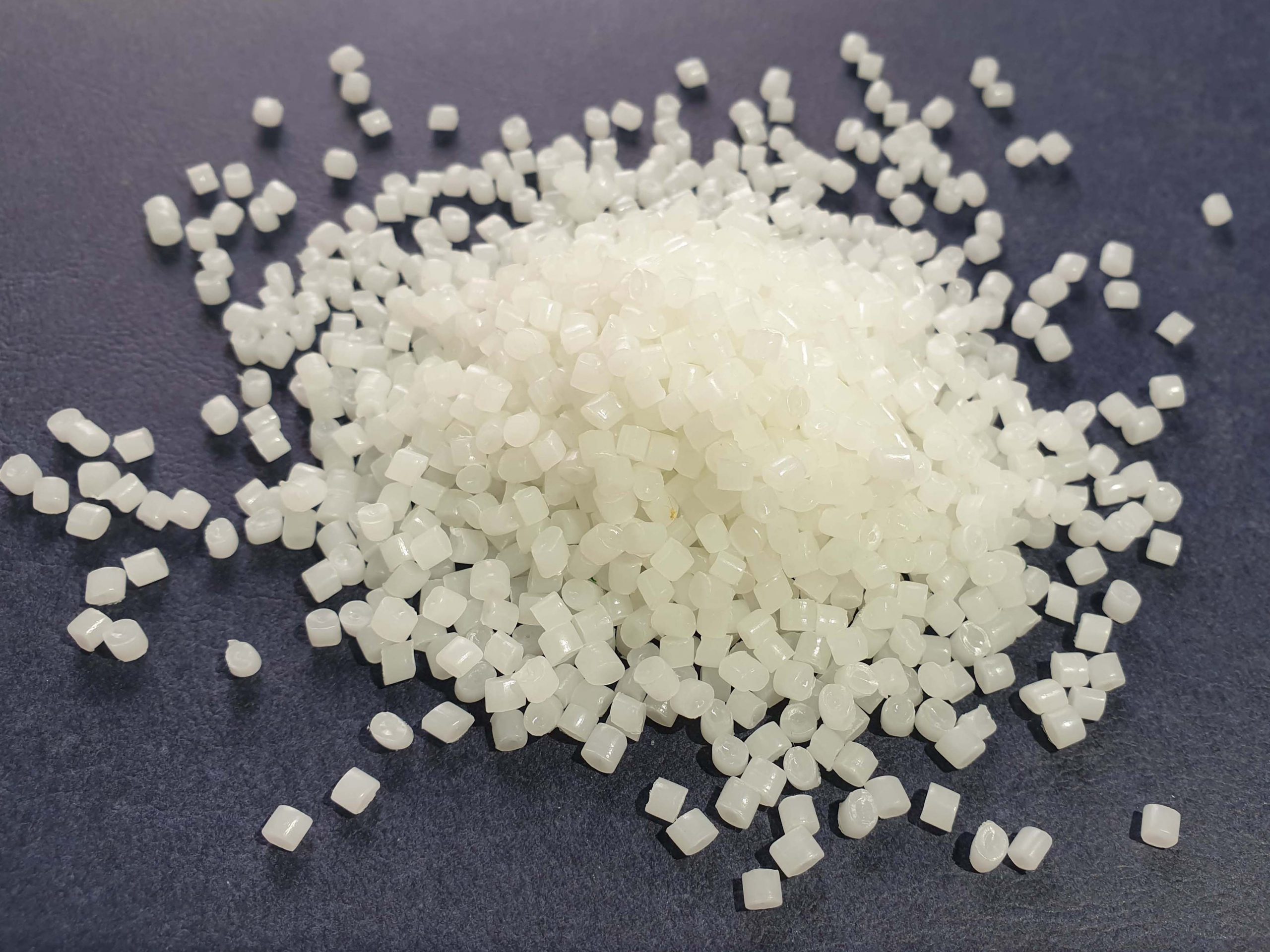

PPA processing aid Masterbatch is an additive used in the production of high-quality products, helping the production process achieve the most optimal performance as well as the highest aesthetics for the product.

PPA Masterbatch Specifications

| Base plastic | PE, PP |

| Usage rate | 2~5% |

| Usage | PE, PP, PS, PVC, EVA |

Features and Benefits

- Improves product surface conditions;

- Reduces surface defects such as, melt fracture, porosities, burrs, etc.

- Eliminates die build-up.

- Improves dimension stability & controllability.

- Improves color/other additives dispersion.

- Reduces gel formation.

- Reduces crystallization.

- Increases Production Capability;

- Reduces internal (Extruder) pressure.

- Reduces the power consumption by the Extruder.

- Reduces heat transition within the Extruder.

- Reduces downtime.

- Reduces time taken for color change.

- Reduces Cost

- Allows effective use of lower MFI resins.

- Allows extrusion of temperature sensitive Resins.

- Using for polymer with maximum temperature 220oC

Applications

- Using in film blowing, injection molding, pipe/profile extrusion, fiber spinning, casting,…

- Using in PE, PP, PS, PVC and EVA applications,…

Packaging and Storage

- 20kg/bag (PP or PK bag)

- PPA Masterbatch when stored in a clean and dry environment at the temperature below 27°C (80°F) can be used within two years.

Factory: Binh Luc industrial and minor handicraft cluster, Trung Luong commune, Binh Luc district, Ha Nam province, Viet Nam

Ha Noi Office: 2nd Floor PUNACO Building, 352 Giai Phong, Thanh Xuan district, Ha Noi, Viet Nam

Tel: +84-24-3215-1458 Fax: +84-24-3215-1458

Ho Chi Minh Office: No 9, 270 street, Nam Hoa Urban area, Phuoc Long A ward, 9 district, Ho Chi Minh City, Viet Nam

Website: www.CPIplastic.com

Email: info@cpiplastic.com - sales@cpiplastic.com