Features:

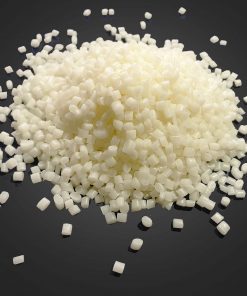

Desiccant Masterbatch can solve the moisture problem of recycled or new raw material avoid drying time to save processing costs of plastics production so as to achieve a kind of superior performance environmental friendly material. It is made by different producing art from normal Desiccant Masterbatch. Its lifetime reaches 24 hours after opening the packaging bag. It has better glossiness and disperse than normal Desiccant Masterbatch.

Advantages:

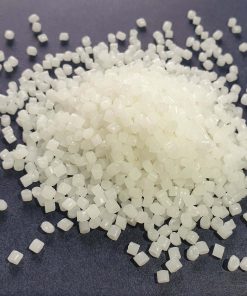

Long lifetime after opening the packaging bag, reaches 24.

This is a modified desiccant masterbatch produced with a new technology.

This desiccant masterbatch keep stable at normal temperature in dry place. It starts absorb moisture from 140 centigrade degree.

Package, Transportation and Storage:

25kgs/carton.

Note to avoid moisture, isolation and breakage in transportation.

Applications:

For HDPE, LDPE,PP Blowing Film, high end bags especially shows its prominent advantages.

For Recycled or new HDPE, LDPE, PP pipe, Sheet, and Various Shapes of Injection Molding Products.