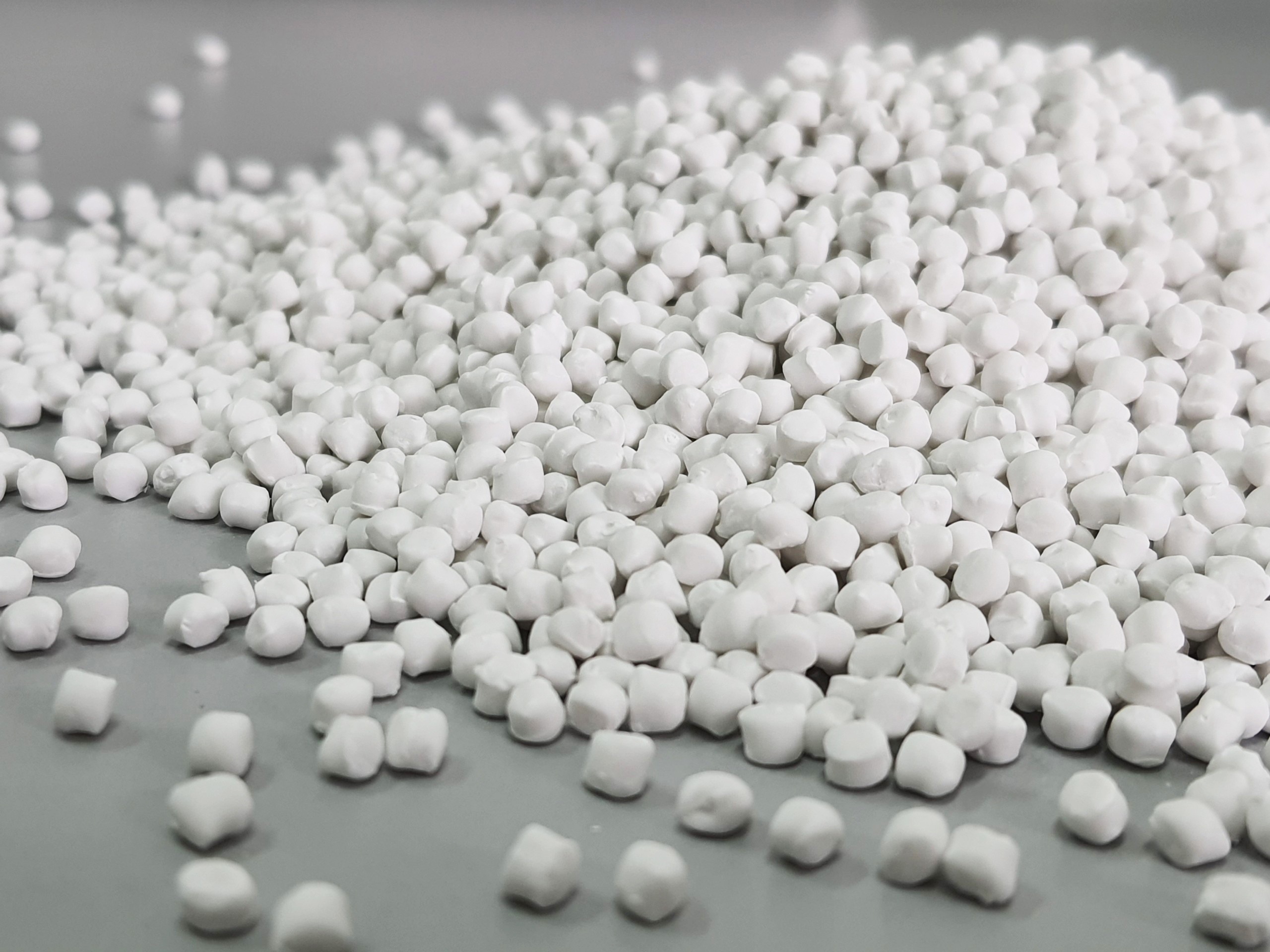

PE Filler Masterbatch

PE Filler Masterbatches is compounded of high quality filler, polymer resin and other additive agents by twin-screw machine. PE Filler Masterbatch is a Polyethylene based masterbatch containing calcium carbonate. It is natural white with excellent dispersity. It is widely used in the plastic industries (film blowing, blow molding, injection molding, extrusion molding) to reduce the production cost and improve the character of final products.