Plastic knowledge

Production process of virgin plastic

Currently, plastic is a popular material used in most industries, from the production of basic items and household appliances to electronic components and important machinery and equipment. Plastic is divided into two main types based on its origin: “synthetic” and “biological“. Synthetic plastics are derived from crude oil, natural gas or coal. While bioplastics come from renewable products such as carbohydrates, starch, vegetable oils and fats, bacteria and other biological substances. Synthetic plastic is divided into “virgin plastic” and “recycled plastic”. In this article we will learn about production process of virgin plastic.

I. Virgin plastic

Virgin plastic or Primary plastic is one of the products produced during the process of fractional distillation of petroleum, through polymerization and condensation reactions to form macromolecular compounds (polymers). After distillation, petroleum will create different products such as: gasoline, diesel oil, lubricant oil, plastic, bitumen, etc. Of which plastic only accounts for about 4% of petroleum products.

| Products from crude oil | Percentage |

| Gasoline | 42.7% |

| Diesel oil | 27,4% |

| Jet fuel | 5,8% |

| Heavy fuel | 5,0% |

| Asphalt | 4,0% |

| Light fuel | 3,0% |

| Hydrocarbon gas liquid | 2,0% |

| Other (plastics, cosmetics, and textiles) | 10,1% |

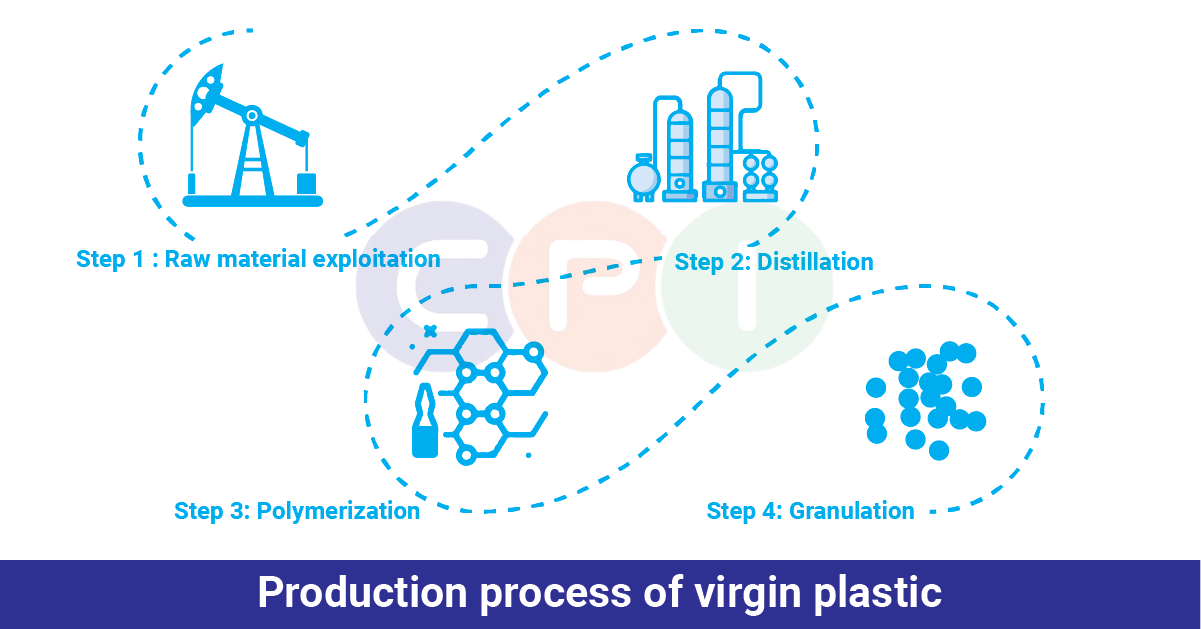

II. Production process of virgin plastic

Basically, most plastics used today are going throught 4 steps:

- Raw material exploitation

- Distillation

- Polymerization

- Granulation

Step 1: Raw material exploitation

The raw materials are mostly crude oil and natural gas, but also coal. This is a complex mixture of thousands of compounds that need to be processed afterward.

Step 2: Distillation

Once extracted, the raw material undergoes a refining process that turns the crude oil into various petroleum products – these products are converted to produce useful chemicals including “monomers” (basic elements of polymers).

In the refining process, crude oil is heated in a furnace, then sent to a distillation unit, where the heavy crude oil is separated into lighter components called fractions. One of these, called naphtha, is an important compound for making large amounts of plastic. Besides, plastic can also be synthesized from other raw materials such as natural gas.

Step 3: Polymerization

This is a process in the oil and gas industry in which light olefin gases (gasoline) such as ethylene, propylene, butylene (monomers) are converted into higher molecular weight hydrocarbons or polymers. During this process the monomers are linked into chains. There are 2 different mechanisms for polymerization:

Addition polymerization:

Addition polymerization occurs by introducing a catalyst, typically peroxide, which helps one monomer connect to the next monomer (dimer) and the dimer to the next monomer (trimer), etc. This process is called polymerization. chain leader – because it adds one monomer unit at a time. Common examples of additive polymers are polyethylene (PE), polystyrene (PS), and polyvinyl chloride (PVC).

Condensation polymerization:

Condensation involves combining two or more different monomers by eliminating small molecules such as water. It also needs a catalyst for the reaction to occur between adjacent monomers. This is called incremental growth; For example, you can add an existing series to another series. Common examples of condensation polymers are polyester (PET) and nylon (PA).

Step 4: Granulation

During this process different mixtures of raw materials are melted and mixed together to create the resin formula. Then, use some type of extruder to form granules. An extrusion or other molding process then turns these pellets into finished or semi-finished products. Granulation typically occurs on a twin-screw extruder, where plastic pellets are then processed into plastic objects of diverse sizes, shapes, colors with precise properties under specified conditions. predetermined in the processor.

Above is the most popular plastic pellet production process today. Through the article, we hope you can better understand how to produce virgin plastic beads.

If you are looking to buy virgin plastic beads, come to CPI Plastics Vietnam. We provide primary plastic such as PE, PP imported directly from reputable manufacturers in the world. Ensuring competitive prices, stable quality and supply, and long-term cooperation.

Please contact Hotline: 0913.046.902 to get the best price quote.