Chưa được phân loại

The Role Of Polymer Processing Aid Additive In Plastic Production

In the plastics processing and manufacturing industry, the use of additives and processing aids is very important to ensure the quality and efficiency of the final product. An additive that plays an important role in the processing of materials is the polymer processing aid additive (PPA).

I. What is Polymer Processing Aid Additive?

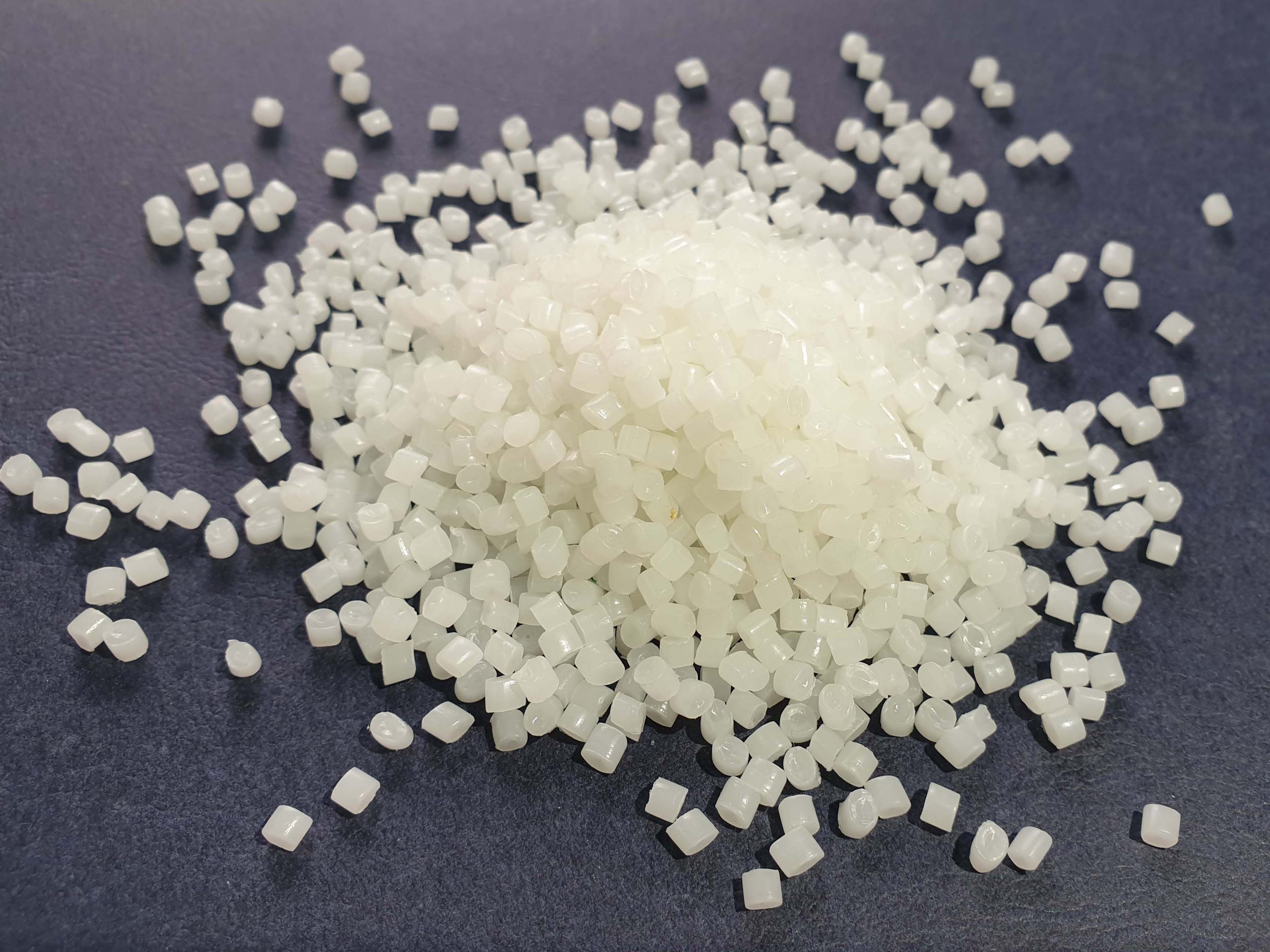

Polymer Processing Aid (PPA) is a type of additive used to improve the processability of polymers, especially in extrusion and injection molding. It helps reduce melt viscosity, improve flow properties and enhance the overall processing performance of the material.

II. Types of processing aids used in the plastics industry

PPA additive have two main groups: Lubricants and Fluoropolymer-based additives.

A. Lubricants

Lubricant additives play an important role in the plastics industry by improving the performance and processability of plastic materials.

These additives are designed to reduce friction and improve flow characteristics during plastic resin processing, resulting in better demoulding, reduced energy consumption, and improved surface finish of the final product.

In addition, lubricant processing aids can also help prevent melt breakage, reduce mold buildup, and improve the overall processing efficiency of plastic materials.

B. Fluoropolymer-based additives

Fluoropolymer-based processing aids are commonly used in the plastics industry to improve the processing and performance of plastic materials. These additives are known for their ability to reduce friction and enhance flow characteristics during processing, resulting in improved production efficiency and reduced energy consumption.

In addition, fluoropolymer-based processing aids can also improve the surface quality and mechanical properties of final plastic products, making them more durable and wear-resistant.

These additives are compatible with a wide range of plastic materials and can be easily incorporated into existing manufacturing processes, making them a popular choice for plastic manufacturers looking to improve product performance.

III. Benefits of using PPA additives in plastic manufacturing

- Reduce energy consumption by lowering processing temperatures and reducing cycle times.

- Improve surface finish and appearance of final products.

- Improve mechanical properties.

- Improve processing efficiency. Reduce plastic viscosity, making it easier to process and mold.

- Reduce color change time.

IV. Applications of PPA additives in the plastic industry

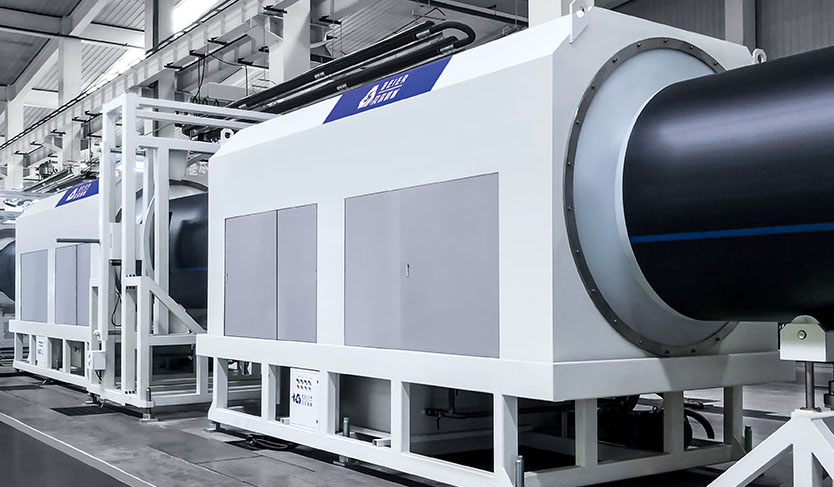

- Pipe extrusion: Improve material flow, prevent sticking to molds or extruders. This can lead to faster production times, reduced energy consumption and improved product quality.

- Automotive and electronic component manufacturing: Improve impact resistance, crack resistance.

- Blowing film: PPA additives reduce friction, allowing the line to operate at high speed.

CPI Plastic is the largest direct manufacturer of Masterbatch plastic additives in Vietnam. Therefore, CPI Plastic is the first choice for factories that need stability in output and quality, in order to meet the production and export needs of customers.

(Refer to the product here: PPA Masterbatch)